Home » Products » Coating Inspection » Coating Thickness Gauges » Wet Film Coating Thickness » Elcometer 3230 Wet Film Wheel

Elcometer 3230 Wet Film Wheel

Product Description

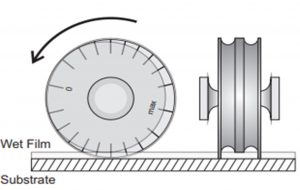

The Elcometer 3230 Wet Film Wheel is a high precision, accurate and easy to use instrument which consists of a set of three wheels. The central wheel is of a smaller diameter and is eccentric relative to the two outer wheels.

By rolling the gauge through a wet coating, the centre wheel eventually touches the film. This point on the scale indicates the thickness. A convenient mounting handle for the wheel is available in two lengths; 15cm & 50cm; please order separately.

When the volume to solids ratio of the coating is known (generally found on the product data sheet supplied by the manufacturer), the wet film thickness can be used to predict the dry film thickness.

Several measurement ranges between 0 to 25µm and 0 to 1000µm are available. Continuous scale produces ±5% measurement accuracy. Suitable for flat and curved surfaces.

The Elcometer 3230 Wet Film Wheel can be used in accordance with:

• ASTM D 1212-A,

• AS/NZS 1580.107.3

• BS 3900-C5-7A*

• ISO 2808-1B

• ISO 2808-7A*

• JIS K 5600-1-7

• NF T30-125

* Standards not in bold have been superseded but are still recognised in some industries.

Specifications

Elcometer 3230 Wet Film Wheel – Specifications

| Part Number | Scale Range | Graduations | Certificate |

| K0003230M001 | 0 – 25µm | 1.25µm | ο |

| K0003230M016 | 0 – 40µm | 2.0µm | ο |

| K0003230M002 | 0 – 50µm | 2.5µm | ο |

| K0003230M003 | 0 – 100µm | 5.0µm | ο |

| K0003230M004 | 0 – 150µm | 7.5µm | ο |

| K0003230M005 | 0 – 200µm | 10.0µm | ο |

| K0003230M006 | 0 – 250µm | 12.5µm | ο |

| K0003230M007 | 0 – 300µm | 15.0µm | ο |

| K0003230M008 | 0 – 400µm | 20.0µm | ο |

| K0003230M009 | 0 – 500µm | 25.0µm | ο |

| K0003230M010 | 0 – 1000µm | 50.0µm | ο |

| Accuracy | ±5% of marked value or 3μm, whichever is the greater | ||

| Dimensions | 50 x 30mm | ||

| Weight | 220g | ||

ο Optional Calibration Certificate available

Packing List

- Elcometer 3230 Wet Film Wheel

- Storage Case

- Operating Instructions

Data Sheet

Standards

Elcometer 3230 Wet Film Wheel – Standards

The Elcometer 3230 Wet Film Wheel can be used in accordance with:

• ASTM D 1212-A,

• AS/NZS 1580.107.3

• BS 3900-C5-7A*

• ISO 2808-1B

• ISO 2808-7A*

• JIS K 5600-1-7

• NF T30-125

* Standards not in bold have been superseded but are still recognised in some industries.

Accessories

Elcometer 3230 Wet Film Wheel – Accessories

| Part Number | Description |

| KT003230N003 | 15cm Wet Film Wheel Handle |

| KT003230N002 | 50cm Wet Film Wheel Handle |

Test Method

Test Method

ISO 2808-7B, BS 3900-C5 method 7B, ASTM D4414-A specify that the wet film wheel should be perpendicular to the substrate and the thickness of the coating should be stated as that indicated on the central wheel – ensuring that the wheel has been rolled from maximum thickness to minimum thickness – thus avoiding surface tension.

The procedure outlined below is for guidance only. Consult the relevant Standard for full details of the applicable test procedure.

1. Using a finger and thumb, hold the wheel by its central spindle with the maximum reading on the scale nearest to the paint film.

2. Place the wheel into the wet film ensuring that the wheel is perpendicular to the film.

3. Roll the wheel across the film through 360°/180° (depending upon standard) and then remove from the surface.

4. Locate the first point on the central wheel where the paint has adhered. Read the wet film thickness from the scale on the side of the wheel at this point.

Repeat the procedure at least twice in different places to obtain representative results.

To use the wheel on pipes, roll the wheel at right angles to the longitudinal axis of the pipe. On rough surfaces, measurements will be made from the surface peaks and therefore will represent the minimum wet film thickness.

Instruction Manual

Elcometer 3230 Wet Film Wheel – Instruction Manual

Elcometer 3230 Wet Film Wheel – Instruction Manual

Video

Elcometer 3230 Wet Film Wheel – Video

The Elcometer 3230 Wet Film Wheel is a high precision, accurate and easy to use instrument which measures the wet film thickness of coatings.

A wet film wheel has two circular outer wheels which rest on the substrate, and a smaller central wheel which is eccentric relative to the outer wheels.

By rolling the gauge through a wet coating, the central wheel eventually touches the film. This point on the scale indicates the thickness.

This Elcometer 3230 Coil Coating Wet Film Wheel is designed for use in the coil coating process. The outer wheels are knurled to allow measurements to be taken on slippery coatings or on fast moving substrates.

Elcometer offer a wide range of wet film wheels to measure wet films of various thicknesses.