Home » Products » Coating Inspection » Surface Preparation » Roughness – Machined Ra » Elcometer 7062 MarSurf PS10 Roughness Tester

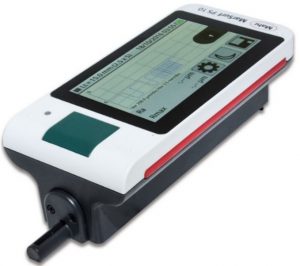

Elcometer 7062 MarSurf PS10 Roughness Tester

Product Description

The Elcometer 7062 MarSurf PS10 Surface Roughness Tester is a light weight and portable measuring solution for the range of surface roughness measurements required for compliance to International Standards.

In protective coating applications there is a requirement to measure surface roughness.

With 31 surface parameter settings available the Elcometer 7062 MarSurf PS10 Surface Roughness Tester can display all parameters that comply to National & International Standards.

These values include peak-to-valley profile measurement in combination with an assessment of the frequency of peaks within the sample area.

The unit is also suitable for assessing surface roughness conditions in a wide range of general industrial applications; particularly where the sample is too large to bring to the laboratory.

The Features of the Elcometer 7062 MarSurf PS10 Surface Roughness Tester

• Multi-Lingual Display: All the required information is displayed on screen in a choice of 17 languages.

• Flexible: Can be used in virtually any position; horizontally, vertically, upside down. A height adjustment accessory to accommodate various sample sizes is supplied with each gauge as standard.

• Integrated Calibration Standard: No external calibration standard is required; provides greater ease of use.

• Removable Drive Unit: Drive unit can be removed from main unit and used with an extension cable (included) to allow for measurement in hard to reach areas.

• Stylus pick-up with removable protection: 2µm diamond stylus tip with a measuring force of 0.7 mN. Different stylus’ are available for various applications.

|

|

|

The Elcometer 7062 MarSurf PS10 Surface Roughness Tester can be used in accordance with:

• ASTM D7127

• ASME B46

• DIN 4768*

• EN 10049

• ISO 4287

• ISO 4287/1*

• JIS B 0601

• SSPC PA 17

* Standards not in bold have been superseded but are still recognised in some industries.

Specifications

Elcometer 7062 MarSurf PS10 Roughness Tester – Specifications

| Part Number | Description | Certificate |

| K7062M001 | Elcometer 7062 MarSurf PS10 Surface Roughness Tester | ● |

| Unit of Measurement | Metric, Imperial | |

| Measuring Principle | Stylus Method | |

| Stylus Pick-Up Supplied | Inductive skidded stylus pick-up, 2µm stylus tip, measuring force approx. 0.7 mN (Other stylus pick-ups are available) | |

| Parameters | DIN/ISO – Ra, Rq, Rz, Rmax, Rp, Rpk, Rk, Rvk, Mr1, Mr2, A1, A2, Vo, Rt, R3z, RPc, Rmr, RSm, Rsk, CR, CF, CL, R, AR, Rx, JIS – Ra, Rq, Ry, RzJIS, tp, RSm, S, ASME – Rp, Rpm, RPc, Rsk, tp, MOTIF – R, AR, Rx, CR, CF, CL | |

| Measuring range | 350µm | |

| Profile resolution | 8nm | |

|

Filter |

Phase-correct profile filter (Gaussian filter) according to DIN EN ISO 16610-21 (formerly ISO 11562), special filter according to DIN EN ISO 13565-1, Is filter according to DIN EN ISO 3274 (can be switched off) |

|

| Cutoff lc | 0.25mm, 0.8mm, 2.5mm; automatic | |

| Traversing length Lt | 1.5mm, 4.8mm, 15mm; automatic | |

| Traversing length (acc. to MOTIF) | 1mm, 2mm, 4mm, 8mm, 12mm, 16mm | |

| Short cutoff | Selectable | |

| Evaluation length ln | 1.25mm, 4.0mm, 12.50mm | |

| Number n of sampling lengths | Selectable: 1 to 16 | |

| Calibration function | Dynamic | |

| Memory capacity | 3,900 profiles, 500,000 results | |

| Other functions | Blocking of settings (code-protected), date/time | |

| Battery | Rechargeable battery 100V to 264V power supply | |

| Interfaces | USB, MarConnect (RS232) | |

| Dimensions | 160mm × 77mm × 50mm | |

| Weight | 500g | |

| Long-range power supply | 100V to 264V | |

- Calibration Certificate supplied as standard

Packing List

- Elcometer 7062 MarSurf PS10 Base Unit

- Drive Unit

- Drive Unit Extension Cable

- 1 x Standard Stylus Pick-up – Inductive skidded stylus pick-up, 2µm stylus tip, measuring force approx. 0.7 mN

- Built-in Battery

- Roughness Standard Integrated into Casing

- Height Adjustment Accessory

- Stylus pick-up Protection

- Universal Charger / Mains Adapter

- USB cable for downloading pdf documents from the unit

- Carry Case with Shoulder Strap and Belt Loop

- Calibration Certificate

- Operating Instructions

Data Sheet

Elcometer 7062 MarSurf PS10 Roughness Tester – Data Sheet

Elcometer 7062 MarSurf PS10 Roughness Tester Data Sheet

Standards

Elcometer 7062 MarSurf PS10 Roughness Tester – Standards

The Elcometer 7062 MarSurf PS10 Surface Roughness Tester can be used in accordance with:

• ASTM D7127

• ASME B46

• DIN 4768*

• EN 10049

• ISO 4287

• ISO 4287/1*

• JIS B 0601

• SSPC PA 17

* Standards not in bold have been superseded but are still recognised in some industries.

Accessories

Elcometer 7062 MarSurf PS10 Roughness Tester – Accessories

| Part Number | Description |

| KT007061P001 |

Stylus pick-up Extension; 80mm Ideal for measuring points located deep within cylinders |

| KT007061P002 |

Stylus pick-up PHT 3-350 For measurements in bores from 3mm diameter |

| KT007061P003 |

Stylus pick-up PHT 11-100 For measurements at recessed measuring points, e.g. in grooves from 2.5mm wide and up to 7.5mm deep |

| KT007061P004 |

Stylus pick-up PHTR 100 For measurements on concave and convex surfaces |

| KT007061P005 |

Stylus pick-up PHTF 0.5-100 For measurements on tooth flanks |

| KT007061P006 |

Stylus pick-up PT 150 Dual-skid stylus pick-up for measurements on metal sheets and roller surfaces according to DIN EN 10049 (SEP) |

| KT007061P007 | Stylus pick-up PHT 6-350 |

| KT007061P008 |

Stylus pick-up PHT 6-350, 5µm Probe Tip For measurements on flat planes, in bores from 6mm, 17mm deep and in grooves from 3mm wide |

| KT007061P010 | Measuring Stand ST-D |

| KT007061P012 |

Measuring Stand Mount Required to fix the Elcometer 7061 to the measuring stand |

| KT007061P011 |

End Face Vee-Block For measuring on flat faces of cylindrical and planar components |

| KT007061P013 |

Adapter Set for Transverse Tracing, Comprising of Adapter for Transverse Tracing and Vee-Block Holder with Vee-Block For hand-held transverse tracing of cylindrical measuring objects |

Test Method

How to use a surface roughness tester

Surface roughness testers consist of a stylus which is mechanically drawn across the surface recording an ‘image’ of the surface roughness across a pre-defined sample length. The measurement technique provides several measurement parameters including:

Rmax: The greatest distance between the highest peak and lowest valley over the sampling length.

Ra: The average surface roughness over the sampling length.

Rt: The distance between the highest peak and the lowest valley within any given sampling length.

Rz: The average distance between the highest peak and the lowest valley over a number of sampling lengths.