Home » Products » Coating Inspection » Surface Preparation » Surface Profiles – Blasted » Elcometer 224 Digital Surface Profile Gauge

Elcometer 224 Digital Surface Profile Gauge

Product Description

The Elcometer 224 Surface Profile Gauge provides the very latest in surface profile measuring technology for measuring profile on either flat or curved surfaces. Fast, accurate and very user friendly, the Elcometer 224 is available with or without memory and Bluetooth®.

The Elcometer 224 meter is available in two different models: Model B and Model T. Each surface profile gauge provides the user with increasing functionality from the entry level Elcometer 224 Model B, to the top of the range Elcometer 224 Model T, with memory, alpha-numeric batching and Bluetooth® communication.

Standard and armoured probes are available for the separate models, providing even greater measurement flexibility. Elcometer surface profile probes are supplied with a glass zero plate, calibration test foils (nominal values 125µm & 508µm and an Elcometer Test Certificate).

Features Elcometer 224 Digital Surface Profile Gauge

- Accurate, immediate and repeatable results

- Integral & separate probe variants for flat and convex* surfaces

- The separate probes can now measure on pipes and tanks

- Tough tungsten carbide user replaceable tip, can be used for up to 20,000 readings

- Stores up to 150,000 readings in alpha numeric batches (Model T only)

- Auto rotating display with tap awake feature

- Cost per test is significantly lower than other test methods

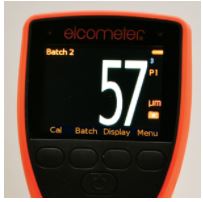

- Large backlit screen makes viewing readings easy

- Digital display prevents reading interpretation errors

- Intuitive menus in multiple languages enables use straight from the box

- Dust and water resistant rugged design equivalent to IP64

- Ergonomic design for comfort during continuous use

- 2.4” Colour screen provides enhanced reading visibility at all angles

- Fast reading rate at 60+ readings per minute

- Review batch data or last 20 readings in a graph format

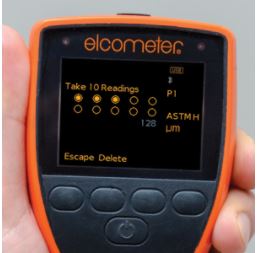

- Counted average mode stores the average value of a preset number of readings (Model T only)

- USB and Bluetooth® data output to ElcoMaster® (Model T only)

| User Friendly

|

The Elcometer 224 surface profile meter is available in two different models: Model B and Model T. Each surface profile gauge provides the user with increasing functionality – from the entry level Elcometer 224 Model B, to the top of the range Elcometer 224 Model T, with memory, alpha-numeric batching and Bluetooth® communication.

Standard and armoured probes are available for the separate models, providing even greater measurement flexibility. Elcometer surface profile probes are supplied with a glass zero plate, calibration test foils (nominal values 125µm & 500µm) and an Elcometer Test Certificate.

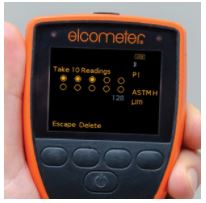

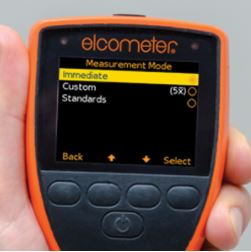

3 Measurement Modes

Whichever test method or Standard you are working to the Elcometer 224 Digital Surface Profile Gauge has a range of easy to use Measurement Modes.

|  |  |

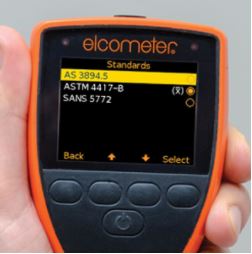

Custom Mode In Custom mode, simply select to take either 5 or 10 readings per measurement then specify either the average, highest or lowest measurement of each set of readings to be displayed and saved into the batch memory2. | Standards Mode Select the International Standard you are working to and the Elcometer 224 will automatically set the data collection method accordingly. When selecting ASTM D 4417, you can even choose if the gauge stores the average or highest reading as the measurement. | Immediate Mode Take individual peak-to-valley measurements and save into the batch memory2. The Elcometer 224 automatically calculates and displays key statistics whilst you’re inspecting, and you can set limits so the gauge will alarm whenever the reading is outside a predefined acceptable range. |

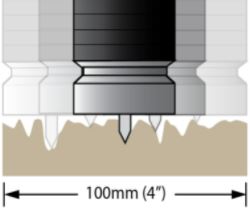

How to measure surface profile

| 1. Ensure probe is 90° to substrate to ensure accurate readings and calibrate the gauge on a glass zero tile. 2. To take one spot measurement, take either 5 or 10 readings within a 100mm diameter area. 3. The measurement displayed is either the average peak-to-valley height or the maximum reading of the 5 or 10 readings, depending on which measurement mode you have selected. 4. To establish the average surface profile of an area, record 5 spot measurements for each 1m x 1m area. |

Wireless Connectivity

| Instantly transfer readings, statistics, and limits; via USB or Bluetooth®; to your PC or mobile device, using ElcoMaster® or your own software application, creating professional inspection reports in minutes. Fast, accurate and very user friendly, the Elcometer 224 Surface Profile Gauge is available with or without memory and Bluetooth®. |

The Elcometer 224 Digital Surface Profile Gauges can work in accordance with:

- ASTM D 4417-B

- SANS 5772

- SSPC PA 17

- US Navy NSI 009-32

- US Navy PPI 63101-000

Specifications

Elcometer 224 Digital Surface Profile Gauge – Model Options

| Part Number | |||

| Integral Gauge | Separate Gauge^ | Description | Certificate |

| E224C-BI | E224C-BS | Elcometer 224 Model B Digital Surface Profile Gauge | ● |

| E224C-TI | E224C-TS | Elcometer 224 Model T Digital Surface Profile Gauge | ● |

^ Probes are supplied separately

● Test Certificate supplied as standard.

Elcometer 224 Digital Surface Profile Gauge – Technical Specifications

| Display information | 2.4″ (6cm) QVGA colour TFT display, 320 x 240 pixels | |

| Battery type | 2 x AA dry cell batteries, rechargeable batteries can also be used | |

| Battery life | Approximately 24 hours of continuous use at 1 reading per second# | |

| Minimum Headroom | Integral: | 185mm |

| Separate: | See Accessories | |

Gauge dimensions (h x w x d) | Integral: | 168 x 73 x 37mm |

| Separate: | 141 x 73 x 37mm | |

Gauge weight (including batteries) | Integral: | 218g |

| Separate: | 161g | |

| Measurement range | 0-500μm | |

| Probe tip | Tungsten carbide tip 60° angle; Tip Radius: 50μm | |

| Operating temperature | -10 to 50°C | |

| Storage temperature | -10 to 60°C | |

| Accuracy | ±5% or ±5μm* | |

| Resolution | 1μm | |

* Whichever is the greater

# Using default settings & lithium batteries, alkaline or rechargeable batteries may differ.

Elcometer 224 Digital Surface Profile Gauge – Product Features

| ■ Standard Model B | □ Optional Model T | |

| Fast, accurate reading rate; 50+ readings per minute^ | ■ | ■ |

| Repeatable & reproducible measurements | ■ | ■ |

| Easy to use menu structure; in 30+ languages | ■ | ■ |

| Tough, impact, water & dust resistant; equivalent to IP64 | ■ | ■ |

| Bright colour screen; with permanent back light | ■ | ■ |

| Scratch & solvent resistant display; 2.4″ (6cm) TFT | ■ | ■ |

| Large positive feedback buttons | ■ | ■ |

| Flat & convex surfaces* | ■ | ■ |

| USB power supply; via PC | ■ | ■ |

| Test certificate | ■ | ■ |

| 2 year gauge warranty† | ■ | ■ |

| Automatic rotating display; 0°, 90°, 180° & 270° | ■ | ■ |

| Ambient light sensor; with adjustable auto brightness | ■ | ■ |

| Emergency light mode | ■ | ■ |

| Gauge software updates¹ via ElcoMaster® Software | ■ | ■ |

| Data output | ■ | ■ |

| • USB; to computer | ■ | ■ |

| • Bluetooth®: to computer, Android™ & iOSǂ devices | ■ | |

| Measurement modes; Immediate, Custom, Standards | ■ | ■ |

| On screen statistics | ■ | ■ |

• Number of readings; η, Mean (average); x, Standard deviation; σ, Highest reading; Hi, Lowest reading; Lo, Coefficient of variation; CV% | ■ | ■ |

| High & low limits; definable audible & visual alarms | ■ | |

| • Number above high limit | ■ | |

| • Number below low limit | ■ | |

| ElcoMaster® Software & USB cable | ■ | |

| Date and time stamp for each reading | ■ | |

| Replaceable screen protectors | ■ | ■ |

| Protective case | ■ | ■ |

| Plastic transit case | □ | ■ |

| Measurement range | 0-500μm | 0-500μm |

| On-screen calibration instructions; in 30+ languages | ■ | ■ |

| Number of batches | 2.5 | |

| Gauge memory; number of readings | Last 5 | 150 |

| Delete last reading | ■2 | ■ |

| Limits; user definable audible & visual pass/fail warnings | ■ | |

| • Gauge (g) or gauge & batch specific (gb) limits | gb | |

| Batch types; normal, counted average | ■ | |

Batch statistics; Average peak-to-valley, Average Max peak-to-valley, Standard deviation, σ; Highest reading, Hi; Lowest reading, Lo; Coefficient of variation, CV% | ■ | |

| Review, clear & delete batches | ■ | |

| Copy batches and calibration settings | ■ | |

| Alpha-numeric batch names; user definable on the gauge | ■ | |

| Fixed batch size mode; with batch linking | ■ | |

| Trend Graph; last 20 readings | ■ | |

| Review batch graph | ■ |

^ Up to 25 readings per minute for the convex probe

* USA Patent Number: 9,261,345

† The Elcometer 224 is extendable within 60 days from date of purchase, free of charge, to 2 years

¹ Internet connection required

ǂ Visit www.elcometer.com/sdk to find out how to integrate Elcometer’s MFi certified products to your App

2 Up to the last 5 readings can be deleted

Packing List

- Elcometer 224 Digital Surface Profile Gauges

- Glass Zero Tile

- 2 x Calibration Foils†

- Wrist harness

- Plastic Transit Case(T)

- Protective Case

- Screen Protector

- Probe Protection Cap†

- 2 x AA Batteries

- Test Certificate

- Operating Instructions

- USB Cable(T)

- ElcoMaster® Software(T)

Data Sheet

Elcometer 224 Digital Surface Profile Gauge – Data Sheet

Elcometer 224 Digital Surface Profile Gauge Data Sheet

Standards

Elcometer 224 Digital Surface Profile Gauge – Standards

The Elcometer 224 Digital Surface Profile Gauges can work in accordance with:

• ASTM D 4417-B

• SANS 5772

• SSPC PA 17

• US Navy NSI 009-32

• US Navy PPI 63101-000

Accessories

Elcometer 224 Digital Surface Profile Gauge – Probes

Flat Surface Profile Probes

Supplied with either standard cables or armoured metal reinforced heavy duty cables, Elcometer surface profile probes are supplied with a glass zero plate, calibration test foils; nominal values 125 & 508μm and an Elcometer test certificate.

| Technical Specifications |  |  | ||

| Range: 0-500μm | ||||

| Resolution: 1μm | ||||

| Accuracy: ±5% or ±5μm | ||||

| Probe Design | Part Number | Minimum Headroom | Minimum Sample Diameter | Certificate |

| Flat Surface: Standard | T224C500US | 125mm | 25mm | ● |

| Flat Surface: Armoured | T224C500UARM | 165mm | 25mm | ● |

Convex Surface Profile Probes

Supplied with either standard cables or armoured metal reinforced heavy duty cables, Elcometer convex surface profile probes are supplied with a glass zero tile, calibration test foils nominal values 125 & 508μm and an Elcometer test certificate.

| Technical Specifications |  |  | ||

| Range: 0-500μm | ||||

| Resolution: 1μm | ||||

| Accuracy: ±5% or ±5μm | ||||

| Probe Design | Part Number | Minimum Headroom | Minimum Sample Diameter | Certificate |

| Convex Surface: Standard* | T224C500UX | 135mm | 75mm | ● |

| Convex Surface: Armoured* | T224C500UXARM | 175mm | 75mm | ● |

* USA Patent Number: 9,261,345, Elcometer 224 probes are covered by a 1-year warranty

Elcometer 224 Digital Surface Profile Gauge – Accessories

| Part Number | Description |

| T22420053 | Replacement Probe Tips; Pack of 2 with Fixing Tool |

| T22420095 | Replacement Probe Tips; Pack of 5 |

| T22419793 | Probe Tip Protection Cap |

| T22421882C | Certified Calibration Test Kit: 125 & 500μ, Calibration Foils, Glass Zero Tile & Cal Certificate |

| T22420072 | Glass Zero Tile |

| T99921325 | USB Cable |

| T99924797 | USB Bluetooth Adaptor (V2.0+) – for PC’s without Bluetooth |

| T99922341 | Self Adhesive Screen Protectors (x10) |

| T22423371 | Plastic Transit Case |

Instruction Manual

Elcometer 224 Digital Surface Profile Gauge – Instruction Manual

Elcometer 224 Digital Surface Profile Gauge – Instruction Manual

Video

Elcometer 224 Digital Surface Profile Gauge – Video

Discover what surface profile is; why the industrial and protective coatings industry measures it; and how you can take faster, more accurate, and repeatable surface profile measurements using the Elcometer 224 Digital Surface Profile Gauge.

Contents

0:04 – What is surface profile?

1:32 – Surface profile vs. roughness

2:01 – Why does the coatings industry measure surface profile?

2:58 – What surface profile is required?

4:31 – Surface Comparators

4:59 – Replica Tape

5:44 – The new Elcometer 224 Digital Surface Profile Gauge

7:06 – Why you need to take multiple readings

8:39 – The Elcometer 224 and ElcoMaster App

PLEASE NOTE – If you have an Elcometer 224 gauge that was released before 1st March 2019, you can update the software of your gauge to include the new measurement modes feature by connecting the gauge to the latest version of ElcoMaster for PC via USB cable.

In the industrial and protective coatings industry, steel surfaces are blasted not only to remove corrosion or old coatings, but to generate a surface profile prior to re-painting.

The surface profile increases the surface area, and it is this increased surface area which provides a key for the coating to adhere or stick to.

Surface Profile should not be confused with roughness. Surface profile is a measurement of the peak-to-valley height. Surface roughness, on the other hand, is the combined measurements of the surface profile and the frequency of the peaks across a linear length (also known as the peak count).

The coatings industry measures surface profile to avoid corrosion. Corrosion is typically caused when three things come together – a ferrous material (in our case the steel substrate), oxygen (from the air) and moisture. If you can remove just one of the 3 elements, corrosion (or more precisely aerobic corrosion) simply cannot happen.

Applying a coating to the steel provides a barrier between the steel and both the air and moisture, preventing corrosion. So if the coating is damaged, or simply rolls off the surface due to poor adhesion, then the steel will rust, corrode, and in time weaken the structure.

The surface profile required is specified by the coating manufacturer or the coating specification agreed to by all parties, and is directly related to the specified dry film coating thickness being applied.

Typically the surface profile specified is the peak-to-valley height in microns. The coating is also specified in microns, as a dry film thickness. The key here is that the required coating thickness is applied to both the valleys and the peaks, otherwise you get rust spots. If the profile is too high or too low, this can lead to premature coating failures, and ultimately corrosion.

There are a number of ways to measure surface profile:

– Surface Comparators: https://youtu.be/YlLfLZIodKU

– Replica Tape: https://youtu.be/E5Nhhnxz6p4

– A needle depth gauge, such as the Elcometer 224.

With the ability to measure profiles up to 500 microns, on flat or curved surfaces, the Elcometer 224 Digital Surface Profile Gauge provides repeatable and reproducible measurements, accurate to ±5%; can store each reading into memory (150,000 readings in 2,500 batches) – and can instantly transfer them to your PC or mobile device using ElcoMaster; our free, easy-to-use software application, generating professional inspection reports, instantly.

What’s more, the new Elcometer 224’s measurement modes, make sure that you can collect and record the data you need in accordance with your relevant test method, or standard.

Connect the Elcometer 224 to your mobile device via Bluetooth, and either transfer the readings from memory, or transfer each reading into the ElcoMaster App, live as you take them. Once the inspection is complete, you can instantly generate and send the inspection report, anywhere in the world.